Microlearning for Heavy Industry

Lessons from the TikTok Generation

Let’s face it… nobody on the shop floor is going to read a 97-page PDF safety manual.

Attention spans are shrinking, shift demands are rising, and today’s workforce isn’t just younger, they’re used to fast, visual, mobile content. So why are we still delivering training like it’s 1995?

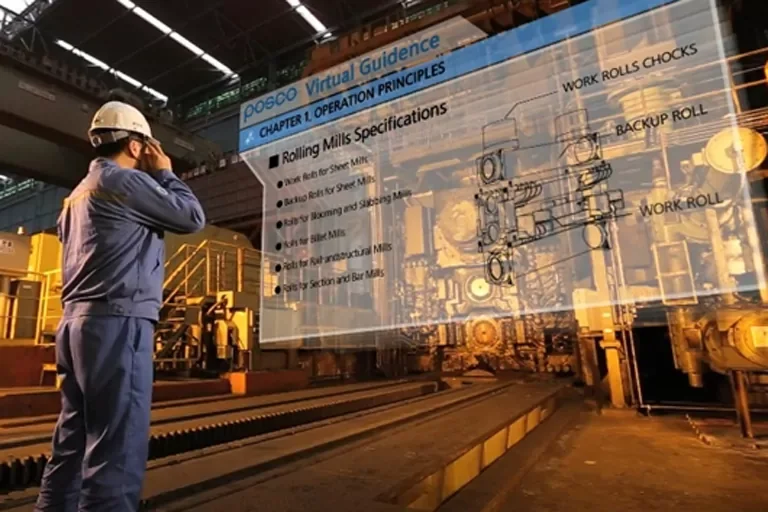

Enter microlearning. Think of it as bite-sized, just-in-time learning, but designed for tradespeople, operator, technicians, and supervisors who don’t have time to sit through an hour-long online module just to remember where the fire extinguisher is.

This isn’t about “TikTok-ifying” your safety program. It’s about meeting people where they’re at—and making sure key skills actually stick.

What Is Microlearning?

Microlearning breaks complex topics into short, focused lessons, often 2–5 minutes long, delivered through visuals, videos, quick quizzes, or mobile-friendly formats. The idea is simple: less content, more impact.

In the world of heavy industry, this might look like:

A 60-second video showing how to apply a lockout tag correctly

A checklist card in a toolbox explaining how to read an arc flash label

A quick refresher quiz on confined space hazards before entry

A wall-mounted infographic on how to use the Root Cause Analysis form

Why It Works (Even in a Heavy Industry)

We work with plants where workers are expected to learn new procedures, adapt to safety changes, and remember compliance rules… all while doing a physically demanding job. Microlearning helps because:

It’s accessible: Workers can review content during toolbox talks, on breaks, or even between tasks

It’s digestible: One point per lesson. Not six. Not twenty. Just one.

It reinforces memory: Repetition in short bursts beats long one-off trainings

It builds culture: Small, visible learning moments keep safety top of mind

And yes, it’s aligned with how Gen Z and Millennials already learn: fast, mobile, and visual. But this isn’t just about the next generation. Seasoned tradespeople also appreciate clarity and speed, they just want to know what works.

Microlearning, Not Micromanaging

There’s a fine line between helpful and patronizing. Good microlearning respects the worker’s intelligence, it doesn’t oversimplify. It assumes they’re competent, busy, and want to do the job safely and efficiently.

We’ve seen success when companies build their own libraries of micro-content:

Create short videos with your own equipment and crew

Use QR codes that link to refresher training beside high-risk areas

Break up longer training into weekly “safety snippets” reviewed at start-of-shift

Don’t Replace, Reinforce

Microlearning is not a substitute for hands-on training, certifications, or detailed procedures. But it’s a powerful reinforcement tool, especially when used between formal sessions or during onboarding.

We’re building microlearning programs for clients in steel, mining, manufacturing and food processing, tailored to their sites, their hazards, and their workforce.

Because it doesn’t matter how good your training is if no one remembers it when it counts.

How SparksPro Can Help

At SparksPro Solutions, we design microlearning content that fits your safety goals and work environment. Whether you want:

A starter pack of safety videos

Custom infographic posters

Toolkits for supervisor-led refreshers

Micro-modules embedded into your e-learning portal

…we’ll make sure your workers don’t just complete training, they actually learn something.

Let’s talk about how microlearning can level up your training, without slowing down your operation.