Qualified… or Just Assigned?

The Hidden Risk of Arc Flash Without Proper Training.

In many industrial workplaces, the phrase “qualified person” appears in electrical safety procedures as if it were a safeguard on its own. But in practice, “qualified” is often reduced to a job title, a checkbox on a training matrix, or an assumption based on seniority.

When it comes to arc flash hazards, that assumption can be deadly.

Arc Flash: Low Frequency, High Consequence

Arc flash incidents don’t happen every day, but when they do, the outcomes are severe.

Arc flash temperatures can exceed 35,000°F (≈20,000°C), hot enough to vaporize copper and steel.¹

Across North America, thousands of workers are treated annually for arc‑related electrical burns, many requiring specialized burn care. ²

Even when incidents aren’t fatal, survivors often face long-term injuries, lost time, and permanent disability. ²

This is why arc flash safety cannot rely on vague definitions of who is “qualified.”

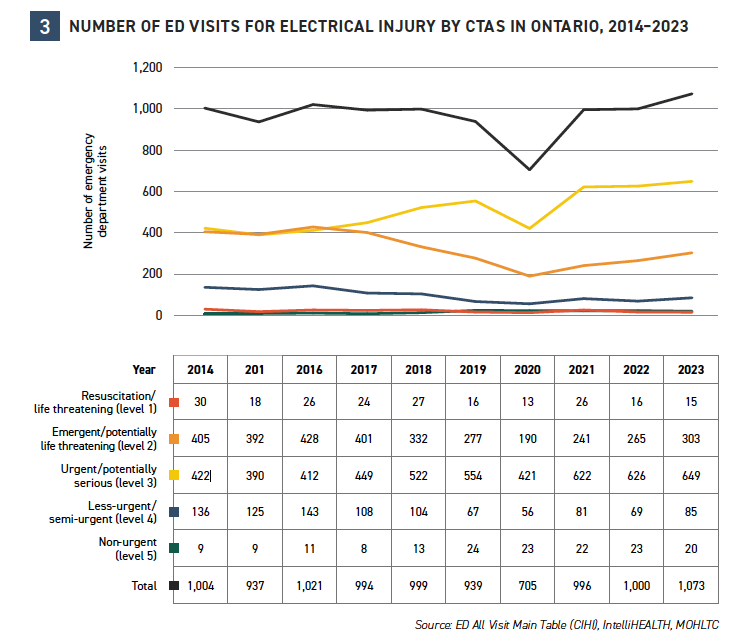

Graph: Emergency Department Visits for Electrical Injuries in Ontario (2014–2023)

Source: OESR 2024, ESA

What the Ontario Data Tells Us

The Ontario Electrical Safety Authority (ESA) publishes one of the most comprehensive electrical injury datasets in Canada. The Ontario Electrical Safety Report (OESR) reveals patterns that matter for arc flash risk:

Between 2014 and 2023, Ontario hospitals recorded 9,672 emergency department visits due to electrical injury.³

Industrial and construction settings consistently rank among the most common locations for these injuries.³

Most electrical injuries were classified as urgent, emergent, or life‑threatening, not minor incidents.³

These are not abstract numbers, they represent real people exposed to electrical energy without adequate protection or understanding.

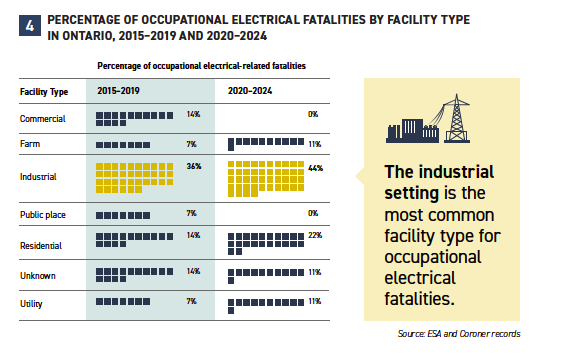

Who Is Most at Risk? Industry and Maintenance Workers

One of the most telling findings in the OESR is where and during what work electrical fatalities occur:

Industrial settings account for the highest proportion of occupational electrical fatalities in Ontario.³

Repair and maintenance activities are repeatedly identified as the most common type of work being performed at the time of fatal incidents.³

Electrical trades account for roughly one‑quarter of occupational electrical fatalities, even though they represent a much smaller portion of the workforce.³

Arc flash exposure lives in this exact space: energized equipment, troubleshooting, testing, maintenance, and “just checking something quickly.”

Graph: Occupational Electrical Fatalities by Facility Type (Industrial, Commercial, Residential)

Source: OESR 2024, ESA

“Qualified…” According to Who?

Standards like CSA Z462 make it clear: a qualified person must have demonstrated skills and knowledge related to the task, including the ability to recognize hazards and take appropriate protective measures.

But in the field, “qualified” often means:

Someone has the right title

Someone completed training years ago

Someone has “always done it this way”

None of those are proof of competency.

Where the System Breaks Down

From real-world assessments, a few patterns show up repeatedly:

Workers are authorized to perform energized tasks without understanding incident energy, arc flash boundaries, or PPE limitations

Training is delivered once, with no practical evaluation

“Qualified” status is never reviewed when equipment, configuration, or work scope changes

The OESR data repeatedly identifies human error and improper procedures as contributing factors in occupational electrical fatalities. That’s not a people problem, it’s a system problem.

What “Qualified” ShouldMean

For arc flash work, qualification should be task‑specific, documented, and defensible. At a minimum, it should include:

Training specific to arc flash hazards, not just general electrical safety

Demonstrated ability to identify hazards on actual site equipment

Understanding of labels, boundaries, and PPE selection

Clear authorization tied to specific tasks, not blanket permission

Training without evaluation is hope, not protection.

Final Thought: Titles Don’t Stop Arc Flashes

The Ontario data tells us something important:

Electrical incidents happen most often during maintenance and industrial work … exactly where arc flash hazards live.

If “qualified” is just a line in a procedure, it won’t protect your people when energy is released.

Real qualification is proven, practiced, and current. Anything less is a risk you don’t need to take.

References:

¹ Canadian Center for Occupational Health and Safety: https://www.ccohs.ca/oshanswers/safety_haz/arc_flash.html

² SAFE Engineering Inc: https://www.safeengineering.ca/arc-flash-dangers-require-effective-ppe/?utm_source

³ OESR 2024, ESA