7 Questions to Ask When Developing Your Electrical Safety Policy

Why the right questions matter — backed by industry safety statistics

Developing an electrical safety policy isn’t just about checking a compliance box. Done right, it protects your people, reduces injuries and fatalities, and strengthens your culture of safety. But too often, organizations adopt generic language or standards without tailoring them to real workplace risks, and that’s where trouble starts.

Before you write or update your electrical safety policy, start by asking the questions below. Each one is grounded in real data about electrical hazards and risk, and will help you build clarity, effectiveness, and relevance into your program.

Question #1. Who Is Truly at Risk in Your Workplace?

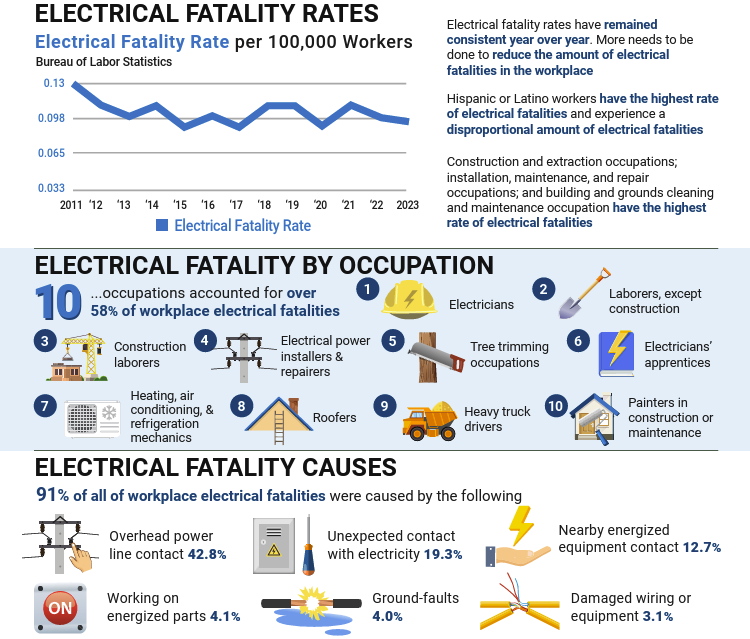

Electrical hazards don’t only affect electricians. According to EFSI, about 400 electrical fatalities occur each year, and 74% of those are in workers not classified as electrical professionals, including maintenance staff, labourers, and other tradespeople.

Ask Yourself

Which job roles in my workplace interact with electrical systems?

Who has been exposed to incidents, even if not officially in an electrical role?

Clarifying who’s at risk helps you decide who needs training, what kind, and how often.

Source: ESFI

Infographic Link: https://www.esfi.org/electrical-fatalities-in-the-workplace-2011-2023/

Question #2. What Types of Electrical Injuries Are We Trying to Prevent?

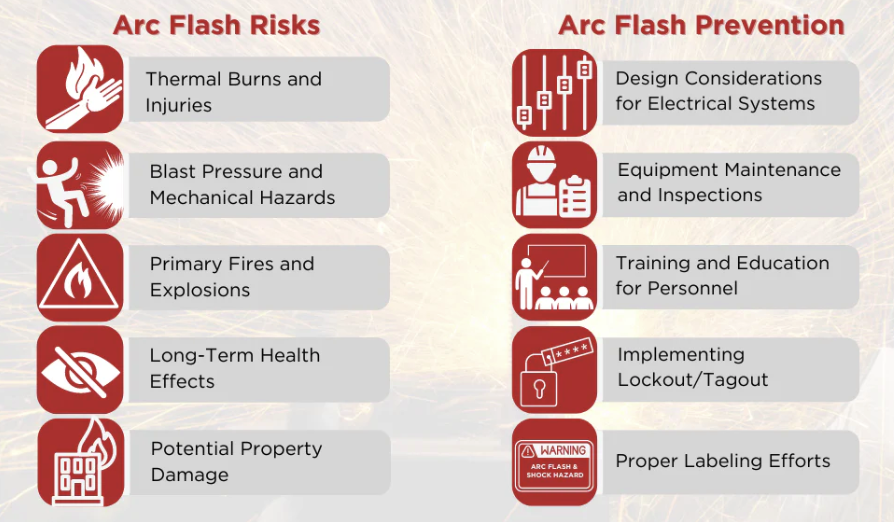

Exposure to electricity can lead to injury far beyond electrical shock. Arc flash incidents alone can reach temperatures of ~20,000 °C (35,000 °F) and cause life‑altering burns, blast injuries, or death.

And arc flash hazards are not rare: industry sources estimate 5–10 arc flash accidents happen every single day in North America, resulting in over 30,000 injuries and 400 deaths a year, with 80% of the fatalities due to burns, not shocks.

It is important to note that arc flash does not only occur in high voltage enviroments, but actually more commonly with 480C and 600V power systems.

Ask Yourself

What kinds of electrical harm have we seen or could we reasonably expect?

Are arc flash hazards clearly identified in our risk assessments?

Question #3. What Does Our Incident Data Show?

Good policy starts with good data. Look at your own injury/near‑miss records, and ask:

What electrical incidents or near misses have occurred in the past 1–3 years?

What conditions were present?

Are there patterns by occupation, task, or area?

Then compare this to national trends: between 2011 and 2023 in the U.S., 1,940 workplace fatalities involved electricity, representing about 5–6% of all workplace deaths.

Understanding real trends, not assumptions, will help you tailor responsible, effective policy language.

Question #4. Do We Clearly Define “Qualified” and “Competent”?

Standards like CSA Z462 and NFPA 70E both emphasize that workers must be Qualified , not just assigned, before performing electrical tasks.

Ask Yourself

How do we define a Qualified Person?

Is that definition tied to training, demonstrated skills, and assessment?

Is it distinct from “experienced” or “licensed”?

A policy that says “work must be done by a qualified person” without defining what that qualification means opens organizations up to risk.

Question #5. How Will Training Be Structured, Delivered, and Measured?

Ask beyond “what training do we offer”?

Who needs initial training vs refresher training?

How is competency demonstrated?

When and how will training be updated?

Are non‑electrical workers receiving appropriate hazard awareness?

One leading industry guideline notes that electrical safety programs should specify who will be trained, how often, and what competencies must be demonstrated — ideally with documentation of testing and assessment.

Source: Creative Safety Supply

Infographic Link: https://ca.creativesafetysupply.com/infographics/arcflash-facts/

Question #6. What Controls Are Required Before Work Begins?

Your policy should be specific about expectations for:

Hazard identification and risk assessment

Lockout/Tagout

Energized work permits

PPE and arc flash/shock boundaries

Standards require these elements but don’t prescribe your exact implementation, that’s where your workplace context matters.

Ask Yourself

Are these procedures documented and accessible?

Do supervisors know how to enforce them?

Are they regularly audited?

Question #7. How Will We Maintain and Improve the Policy Over Time?

A policy shouldn’t be “written once and forgotten”.

Best practice is to build in scheduled reviews, and triggers for review such as:

A serious incident

A change in equipment or processes

Staff turnover or new roles

Regulatory updates

Ask Yourself

How often will the policy be reviewed?

Who is accountable for updates?

How will changes be communicated?

Bottom Line: Ask First, Document After

Electricity isn’t going away, and neither are electrical hazards. But a policy based on reflection, data, and targeted questions protects people and performance.

👉 By asking the right questions first, you don’t just comply — you reduce harm.

Want Help Building Yours?

At SparksPro Solutions, we help teams develop electrical safety policies that:

Reflect real workplace risk

Align with CSA Z462 and other standards

Include targeted training, qualification definitions, and measurable controls

Contact us for a FREE consultation to assess your current program and identify gaps.